When it comes to automobiles, particularly those with manual transmissions, there are several intricate components working together to ensure smooth operation. One such critical component is the bell housing. While often overlooked by the average car owner, the bell housing plays a vital role in the functioning of the engine and transmission system.

In this article, we will dive deep into the world of bell housings, explaining what they are, how they work, why they are important, and how they fit into the broader automotive system. Additionally, we will answer some common questions related to bell housings to give you a well-rounded understanding of this essential car part.

Table of Contents

What is a Bell Housing?

A bell housing is a crucial component that houses the rear end of an engine’s crankshaft and connects it to the transmission. It is typically made from cast iron, aluminum, or steel, and its primary function is to house the clutch and provide a mounting point for the transmission. The bell housing is also responsible for aligning the engine and transmission properly.

The shape of a bell housing is what gives it its name. It is typically bell-shaped, providing the necessary space for the transmission’s input shaft to engage with the engine’s flywheel. This allows the transmission to transmit power from the engine to the wheels.

Main Functions of the Bell Housing

The bell housing has several important functions, some of which are detailed below:

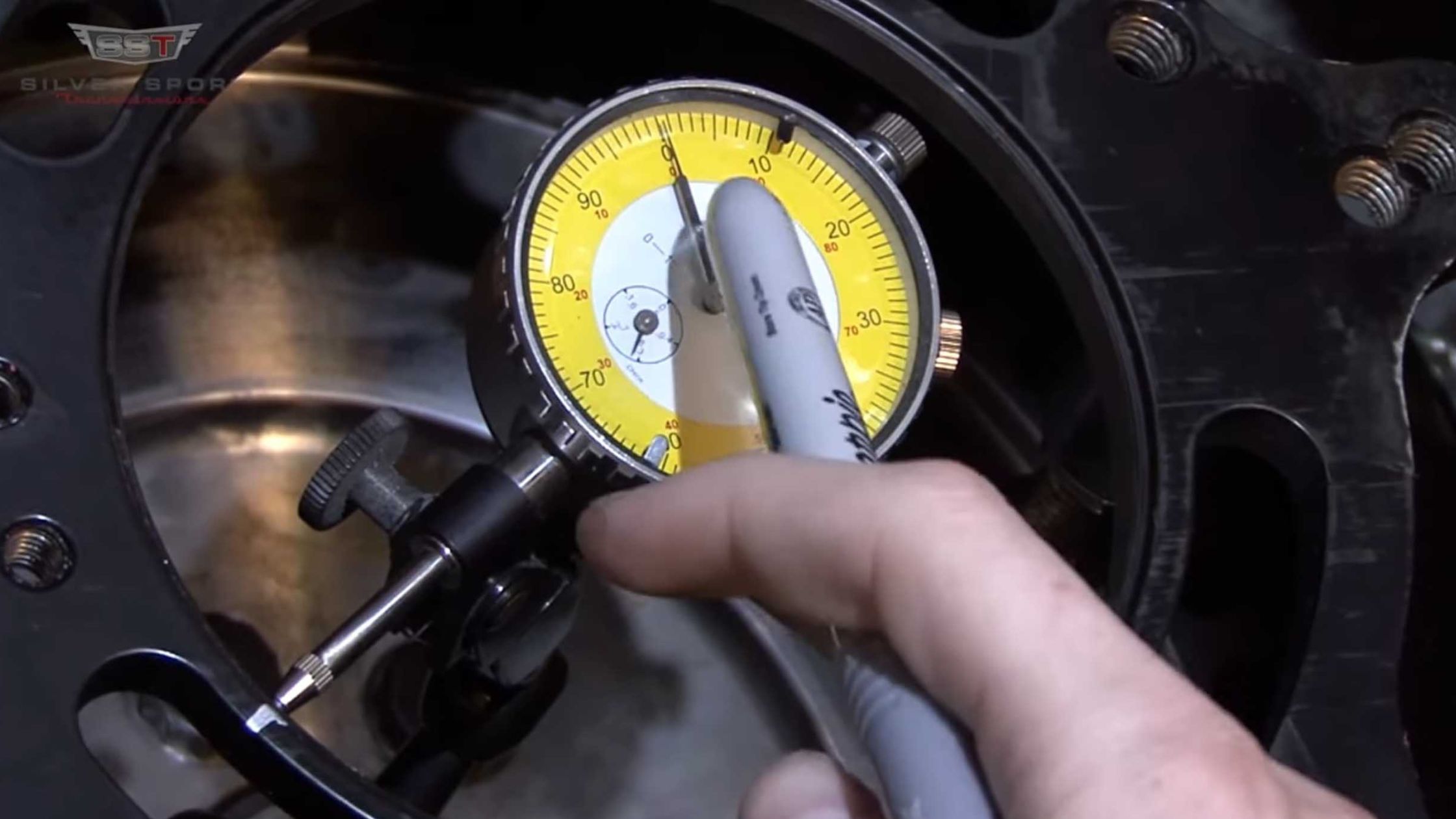

- Transmission Mounting and Alignment The bell housing plays a central role in aligning the engine and transmission. It ensures that both the flywheel and the transmission input shaft are properly lined up. This alignment is crucial for smooth operation, as it allows the transmission to effectively transfer power from the engine to the wheels.

- Clutch Housing In manual transmissions, the bell housing also serves as the housing for the clutch mechanism. The clutch is a vital component in any manual vehicle, allowing the driver to disengage the engine from the transmission when shifting gears. Inside the bell housing, you’ll find the pressure plate, clutch disc, and release bearing, all of which work together to engage and disengage the engine’s power from the wheels.

- Protection and Containment The bell housing serves as a protective casing for the internal components of the engine and transmission. It helps keep dirt, debris, and other contaminants out of the gearbox, ensuring that these critical components remain clean and function smoothly. The bell housing also provides a protective shield to prevent any damage in the event of a mechanical failure.

- Vibration Dampening The bell housing can help absorb vibrations generated by the engine and transmission, which is especially important in performance vehicles where high-speed operation can cause significant engine and drivetrain vibrations.

- Cooling In some designs, the bell housing can also assist with cooling, especially in high-performance applications. Some bell housings are equipped with cooling ducts or are designed to direct airflow to specific areas to prevent overheating.

Components Inside the Bell Housing

The bell housing houses several essential components that facilitate the operation of the manual transmission system:

- Flywheel: The flywheel is a large, circular metal disc that stores rotational energy and helps smooth out engine power fluctuations. It also provides a surface for the clutch to engage.

- Clutch Assembly: The clutch assembly includes the pressure plate, clutch disc, and release bearing. This is the part of the bell housing responsible for connecting and disconnecting the engine from the transmission, allowing for smooth gear shifts.

- Pilot Bearing: The pilot bearing is a small but crucial component located within the bell housing. It supports the input shaft of the transmission and ensures that it spins smoothly, aligning the shaft with the crankshaft.

Types of Bell Housings

Bell housings come in different designs, which vary depending on the vehicle’s engine and transmission type. Some of the most common types include:

- Traditional Bell Housing This is the standard type of bell housing used in most manual transmission vehicles. It connects the engine to the transmission and houses the clutch components.

- Modular Bell Housing A modular bell housing is used in vehicles where a variety of engine and transmission types are used across different models. This type of housing is designed to be adaptable, allowing the same bell housing to work with multiple engine and transmission configurations.

- Hydraulic Bell Housing Some modern vehicles use hydraulic bell housings. These designs incorporate hydraulic components to assist with clutch operation, making shifting gears smoother and reducing the amount of force needed to operate the clutch pedal.

- Lightweight Bell Housing In performance or racing vehicles, lightweight bell housings are often used to reduce the overall weight of the vehicle. These are typically made from aluminum alloys or other lightweight materials and are designed to maintain strength while reducing weight for improved performance.

Materials Used in Bell Housing Construction

Bell housings are made from a variety of materials depending on the application and the desired properties, such as weight, strength, and heat resistance. Common materials include:

- Cast Iron: Cast iron is a durable and cost-effective material used in many standard bell housings. It is resistant to wear and tear and provides good protection for the internal components.

- Aluminum: Aluminum is a lightweight, corrosion-resistant material often used in high-performance vehicles. It provides a good balance between strength and weight and is commonly used in racing or sports car applications.

- Steel: Some bell housings, particularly those used in heavy-duty applications, are made from steel. Steel offers excellent strength and durability, but it is heavier than aluminum and cast iron.

How Does a Bell Housing Work?

The bell housing operates by serving as a housing for several critical components in the drivetrain system. When the engine is running, it spins the flywheel, which in turn transfers rotational power to the clutch assembly. The clutch disc, which is mounted on the flywheel, engages with the pressure plate, which is connected to the transmission’s input shaft. The transmission then transmits power to the wheels.

When the driver presses the clutch pedal, it disengages the clutch from the flywheel, which temporarily disconnects the engine from the transmission. This allows the driver to shift gears without the engine power interfering with the gear selection process. Once the driver releases the clutch pedal, the clutch engages again, and the engine’s power is transferred back to the transmission and wheels.

Importance of Bell Housing Maintenance

While the bell housing itself is relatively low-maintenance, it’s essential to ensure that the components housed inside the bell housing, such as the clutch and flywheel, are in good working condition. Regular inspections and maintenance of the clutch system can prevent problems such as clutch slippage, rough gear shifts, or clutch failure. If any of the parts inside the bell housing are worn or damaged, it can result in poor performance, excessive vibrations, or even complete drivetrain failure.

Common Issues with Bell Housings

Some common issues that may arise with bell housings or the components housed within them include:

- Clutch Failure: If the clutch components inside the bell housing are worn out, the vehicle may experience difficulty shifting gears or even total clutch failure.

- Alignment Issues: If the engine and transmission are not properly aligned due to bell housing issues, the vehicle may experience vibrations, poor shifting, and premature wear of internal components.

- Cracks or Damage: In some cases, bell housings can crack or become damaged, especially in high-performance or off-road vehicles that experience significant stress. A cracked bell housing can lead to the failure of the clutch or other drivetrain components.

FAQs About Bell Housings

1. What happens if the bell housing is damaged? If the bell housing is damaged, it could affect the alignment of the engine and transmission, leading to improper gear engagement, vibrations, or even total failure of the drivetrain. It’s important to inspect the bell housing regularly for cracks or signs of wear.

2. How often should I inspect the bell housing? It’s recommended to have the bell housing and associated components inspected during routine maintenance, particularly if you’re experiencing issues like slipping gears or difficulty shifting. Clutch replacement or adjustments also provide a good opportunity to inspect the bell housing.

3. Can a bell housing be replaced if it’s damaged? Yes, bell housings can be replaced if they become cracked or damaged. However, replacing a bell housing is typically a labor-intensive process that may require removing the transmission and other components to access it.

4. How do I know if my bell housing is failing? Signs of bell housing failure include difficulty shifting gears, unusual vibrations, and clutch slippage. If you experience any of these symptoms, it’s essential to have your vehicle inspected by a qualified mechanic.

Conclusion

The bell housing is an often-overlooked but essential component in the drivetrain system of a manual transmission vehicle. By serving as a protective casing for the clutch and a mounting point for the transmission, the bell housing ensures smooth operation of the engine and transmission. It plays a critical role in aligning components, housing vital parts like the clutch assembly, and protecting the system from contaminants. Proper maintenance of the bell housing and its components is crucial for ensuring optimal vehicle performance and longevity.

Understanding the importance of the bell housing helps car owners appreciate the complexities of their vehicle’s transmission system and how each part contributes to its smooth operation. Whether you’re a seasoned mechanic or just a car enthusiast, the bell housing is a key piece of the puzzle in keeping your vehicle running efficiently.